Mục lục - Table of Contents

SMC conducts blade cleaning for 12 wind turbines at Amaccao Quang Tri Wind Power Project

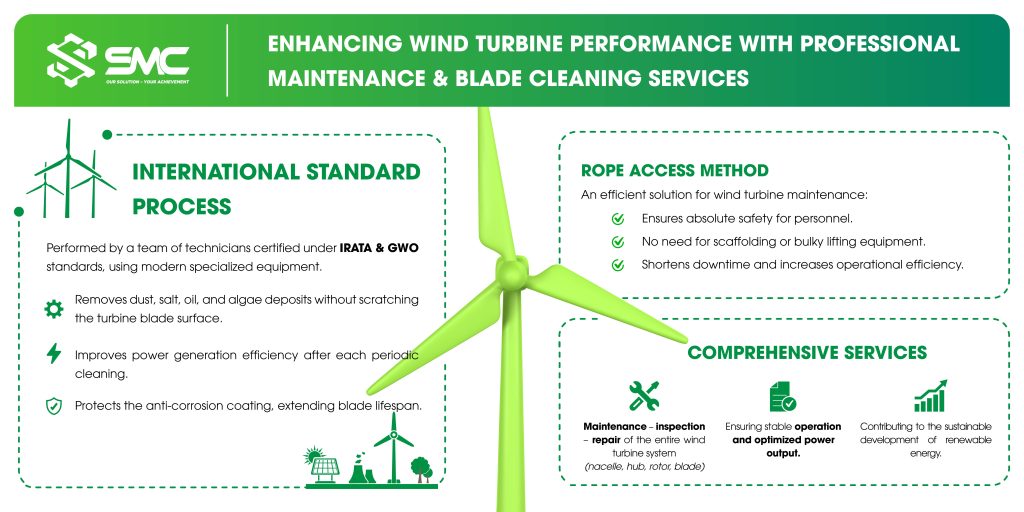

SMC has successfully completed the turbine blades cleaning work for 12 wind turbines under the Amaccao Quang Tri Wind Power Project — marking another milestone in the company’s nationwide Operation & Maintenance (O&M) service network.

The entire process was carried out using the Rope Access method — a globally recognized technique in the wind energy sector for its safety, flexibility, and cost efficiency.

This method allows technicians to precisely access every point on the turbine blades at heights of several dozen meters without the need for scaffolding or bulky lifting equipment, significantly reducing downtime, optimizing project schedules, and ensuring absolute safety during plant operations.

SMC performs wind turbine blade cleaning using Rope Access method.

International-standard procedures

Every cleaning turbine blades process performed by SMC follows strict international safety and technical standards to ensure optimal efficiency while preserving the integrity of the equipment.

SMC’s technicians are internationally trained and certified under IRATA (Industrial Rope Access Trade Association) and GWO (Global Wind Organisation) standards — affirming their professional competence, discipline, and ability to work safely in all terrain and weather conditions.

Standardized maintenance and cleaning steps include:

• – Thorough removal of dirt, salt, grease, and algae from blade surfaces.

• – No scratching or damage to the protective anti-corrosion coating.

• – Noticeable improvement in power generation efficiency after each cleaning cycle.

• – Prolonged blade lifespan and maintained aerodynamic performance.

Regular cleaning plays a vital role in turbine maintenance, eliminating factors that reduce aerodynamic efficiency and preventing energy production losses — ensuring turbines operate at peak performance.

Rope Access method – An efficient solution for wind turbine maintenance

As one of the pioneers in Vietnam applying Rope Access technology for wind turbine maintenance, SMC delivers an optimized solution that balances both performance and safety.

Key advantages of Rope Access:

• – Absolute safety: Strict adherence to control procedures minimizes risks under any weather conditions.

• – Cost and time efficiency: No scaffolding or lifting platforms required.

• – High flexibility: Suitable for all terrains — including mountainous or high-wind areas.

• – Reduced downtime: Enables turbines to return to operation faster, maximizing power generation output.

Rope access method – Effective solution for wind power maintenance

Comprehensive services (O&M wind power project) – Sustainable operational solutions

Beyond turbine blades cleaning, SMC offers a full range of maintenance, inspection, and repair services for wind turbine systems, including:

• – Technical inspection and treatment for nacelle, hub, rotor, and blades.

• – Measurement and early detection of potential faults, with timely corrective actions.

• – Equipment condition assessment based on international standards to ensure long-term stability and safety.

Improve wind turbine performance with professional blade cleaning and maintenance services

SMC’s maintenance and cleaning services not only provide technical and economic benefits for investors but also contribute to the sustainable growth of Vietnam’s renewable energy sector.

With extensive field experience and a team of internationally certified experts, SMC continuously enhances its O&M capabilities, applying advanced technologies tailored to Vietnam’s climate and operational conditions.

SMC is committed to delivering sustainable operational value — improving power generation efficiency, reducing maintenance costs, ensuring absolute safety, and maintaining system reliability throughout the project lifecycle.

Moving toward a green energy future, SMC affirms its position as a trusted technical partner for wind power investors, accompanying renewable energy projects on their journey toward stable, safe, and optimized operation — for a greener and more sustainable Vietnam.